We are,

30 YEARS

Experienced Leading Automation and Engineering Solutions provider

Welcome to,

ADVIKA AUTOMATION AND ENGINEERING SOLUTIONS

We have over 30 years of experience in the field of Industrial Automation, Manufacturing Plant and CNC Maintenance, Design, Development and Manufacturing of Component Validation Test Rigs, Endurance Test Rigs, Equipments and SPMs.

Our Mission is to commit, deliver desirable, timely, satisfying and trustworthy services and products. We stand out as a symbol of Quality and Trust in the field of Automation and Engineering Industry.

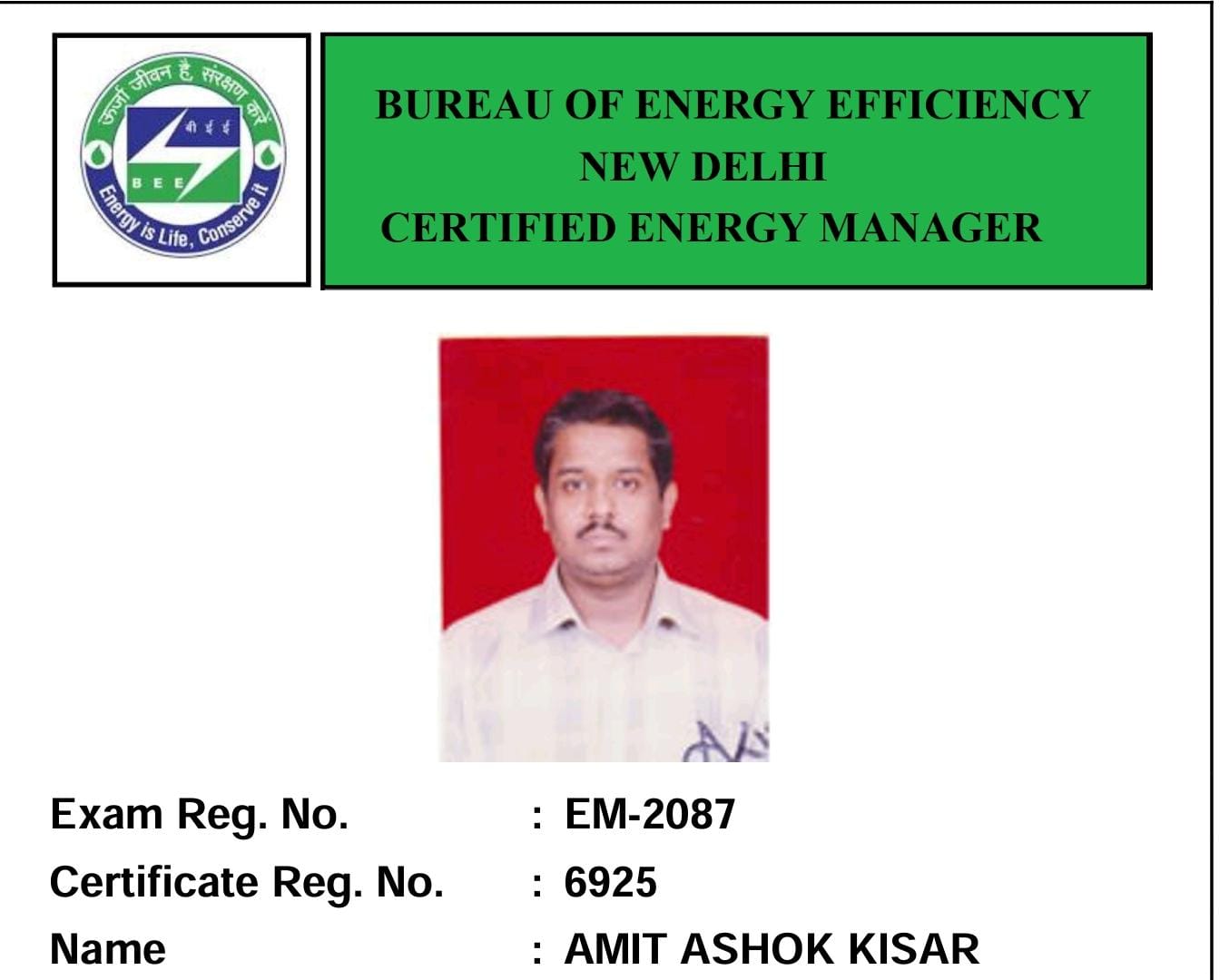

Amit Kisar,

Director

Revolutionize your operations through our expertise in Factory and Process Automation. We bring seamless efficiency to your production processes.

We excel in the Design, Development, and Manufacturing of Specialized Test Rigs. From Component Validation to Endurance and Hydraulic Pulsation Testing, precision is our hallmark.

Our specialization lies in crafting bespoke Special Purpose Machines and equipment to elevate your productivity.

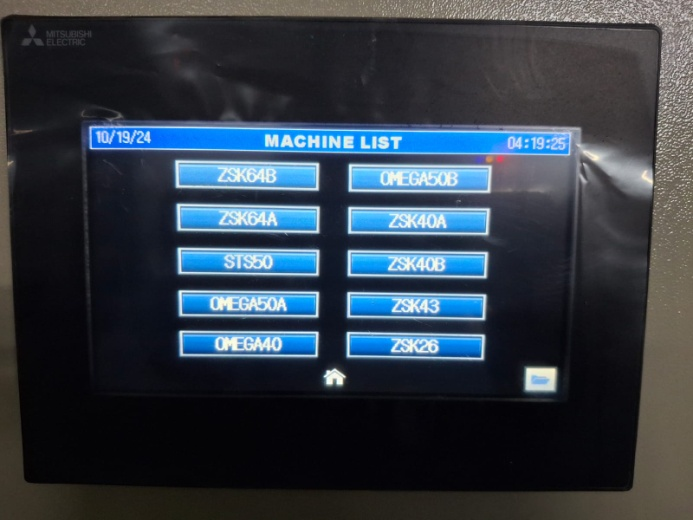

Take command with our PLC, HMI, and VFD-based Control Panels. Our SCADA projects, coupled with Logic Development and PLC programming, provide you with comprehensive control. Additionally, we implement Poka Yoke and Kaizens using PLCs for enhanced operational efficiency.

We’re your one-stop source for all makes and types of Maintenance and Automation Spares. From PLCs and HMIs to VFDs, Servo Drives, Sensors, and Instrumentation, we have you covered.

Optimize your CNC systems with our comprehensive suite of services. From meticulous Maintenance to precise `Retro-fitment’ and Trading of Refurbished CNCs, SPMs, and GPMs, we ensure peak performance.

Ensure uninterrupted operations with our comprehensive suite of Manufacturing Plant Maintenance Services. From Breakdown Maintenance to Preventive and Predictive Maintenance, along with flexible AMCs, we keep your plant running smoothly.

Empower your facility with our tailored Energy Management Solutions. We offer in-depth Energy Auditing and Electrical Auditing services, coupled with innovative Energy Saving Projects. Our expertise extends to Power Quality Analysis, and the implementation of Energy Monitoring Systems, APFC Panels, Power Distribution Panels, AMFs, and advanced Energy Metering Solutions.

Streamline your workflow with our advanced Material Handling Automation solutions. Our offerings include Conveyor Systems and efficient Automatic Loading and Stacking Units for seamless material flow.

Elevate your living and working environments with our state-of-the-art Automation solutions. Whether it’s Home Automation, Office Automation, or a comprehensive Building Management System (BMS), we tailor our solutions to suit your unique needs, ensuring comfort, efficiency, and security.

Stay at the forefront of technological advancement with our Networking Solutions and Industry 4.0 offerings. We provide robust Networking Solutions to keep you connected and competitive. Additionally, we cater to IIoT-related requirements and specialize in Manufacturing Data Management (MDM) for optimized operations.

Enhance your product reliability, productivity, quality, service, efficiency and your plant’s overall equipment effectiveness by using our SaaS, CMMS, EAMS, CRM and MDM Softwares.

Revolutionize your maintenance processes with our cutting-edge software solutions and robust Data Management systems. Our offerings are designed to ensure the seamless operation of your systems, enhancing reliability and efficiency.

- SS, MS, Copper, Brass Fabrications

- Fabricated Enclosure Panels, Enclosures for Electrical application

- Heavy Fabrication Equipments likePressure vessels, Heat Exchangers, Distillation Columns, Vapour Liquid Separators, Falling as well as Forced Circulation Evaporators, Bag Filters and Allied Equipments with Erection and Commissioning.

- Fabricated Sheds

Stay at the forefront of technological advancement with our Networking Solutions and Industry 4.0 offerings. We provide robust Networking Solutions to keep you connected and competitive. Additionally, we cater to IIoT-related requirements and specialize in Manufacturing Data Management (MDM) for optimized operations.

Enhance your product reliability, productivity, quality, service, efficiency and your plant’s overall equipment effectiveness by using our SaaS, CMMS, EAMS, CRM and MDM Softwares.

Revolutionize your maintenance processes with our cutting-edge software solutions and robust Data Management systems. Our offerings are designed to ensure the seamless operation of your systems, enhancing reliability and efficiency.

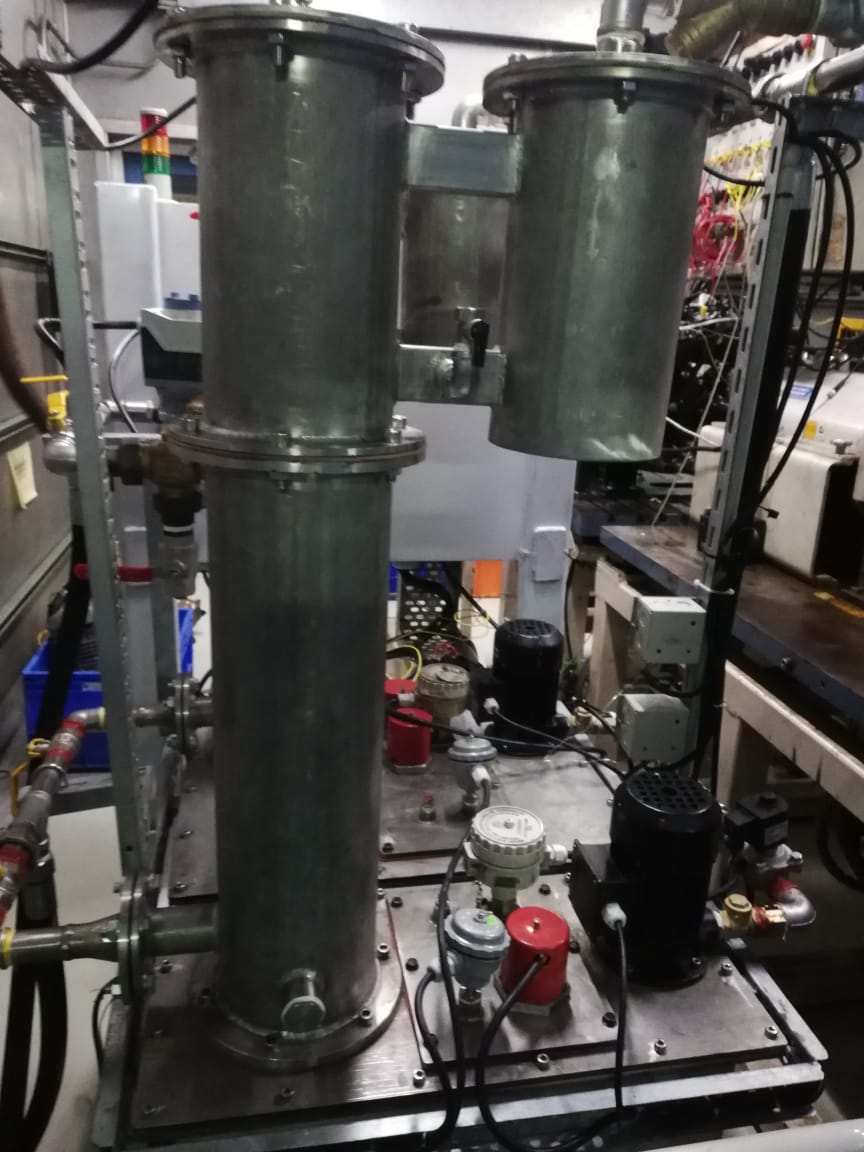

Wide range of Test Rigs

Durability / Reliability Test Rigs….

-

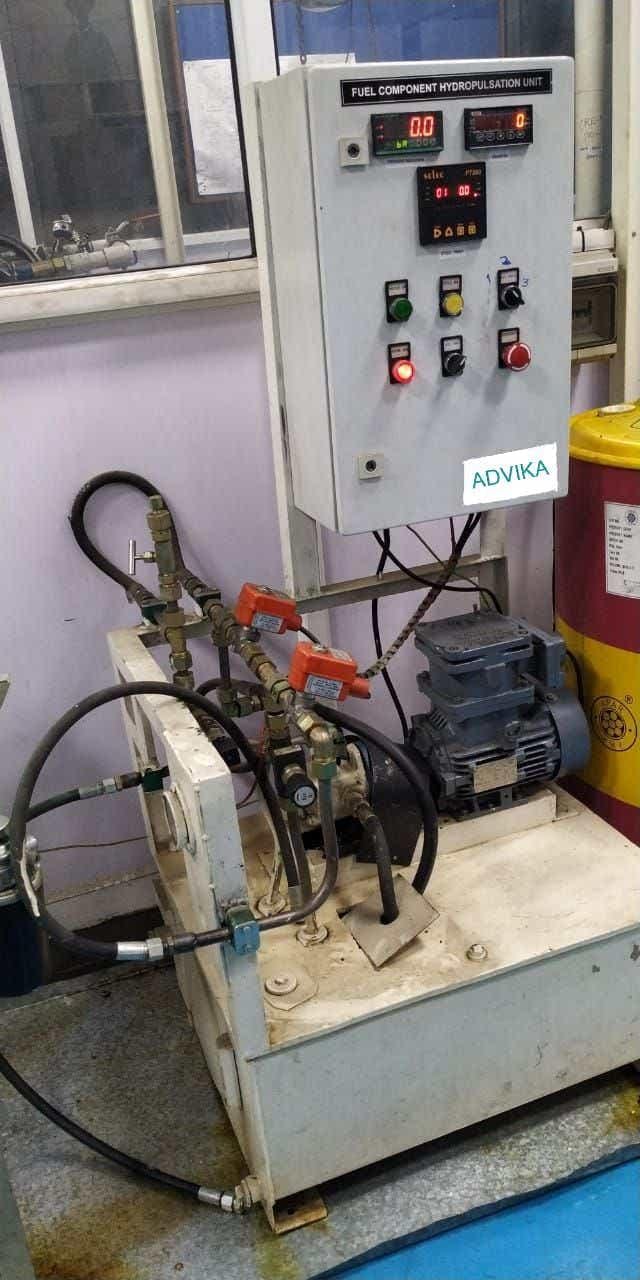

Hydro Pulsation Test Rigs for Engine Fuel Filter

> Pressure 0 to 25 bar based on ISO 4548 -5-2013(E) Standard -

Hydro Pulsation Test Rigs for Low Pressure Fuel Circuit

> Pressure 0 to 25 bar based on ISO 4548 -5-2013(E) Standard -

Hydro Pulsation Test Rigs for Engine Oil and Coolant Filters

> Oil Pressure 0 to 25 bar and Coolant Pressure 0 to 10 bar with 55 deg ℃ -

Hydro Pulsation Test Rigs for Engine Oil Coolers

> Oil Pressure 0 to 15 bar based on ISO 4548 -5-2013(E) Standard

-

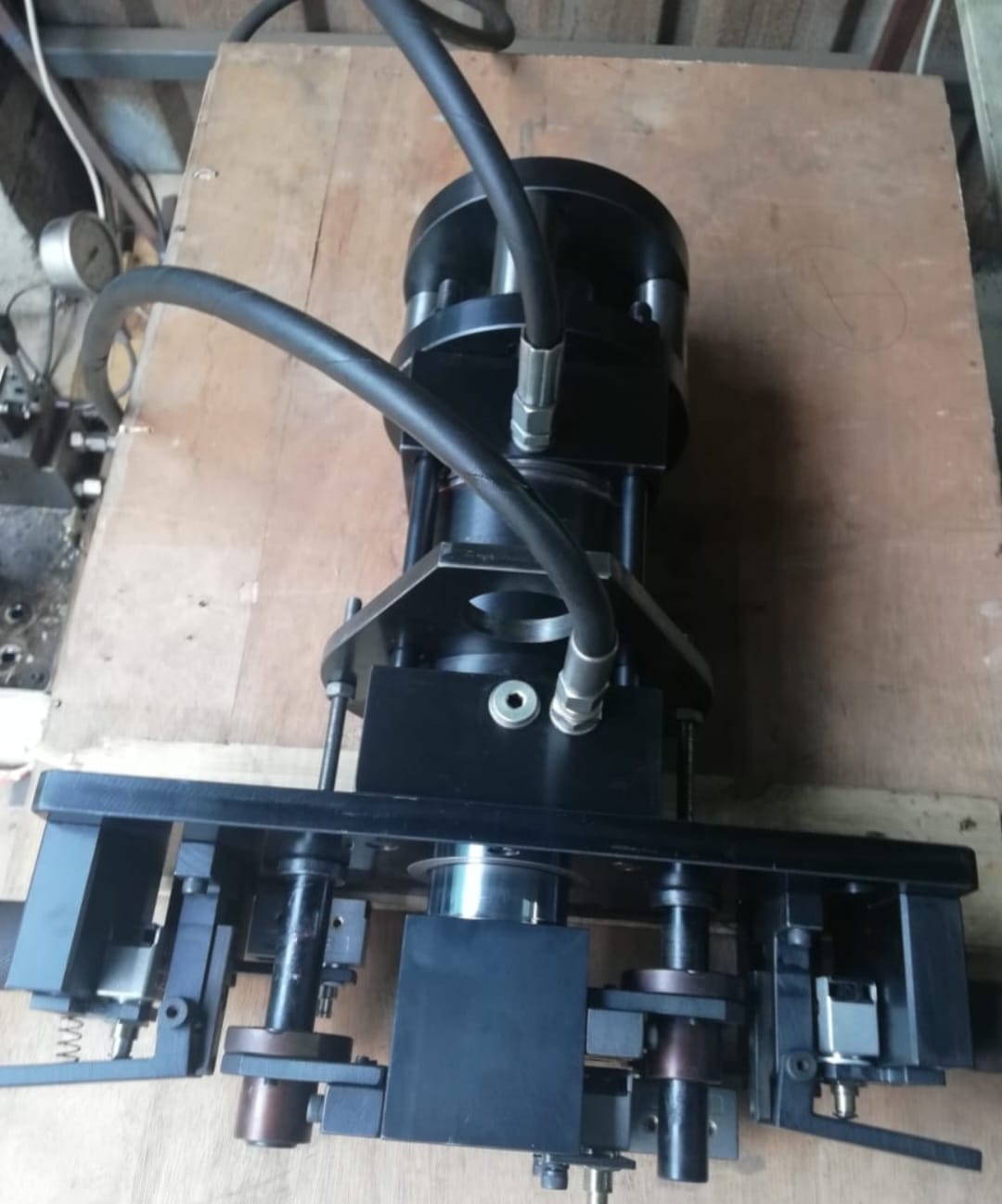

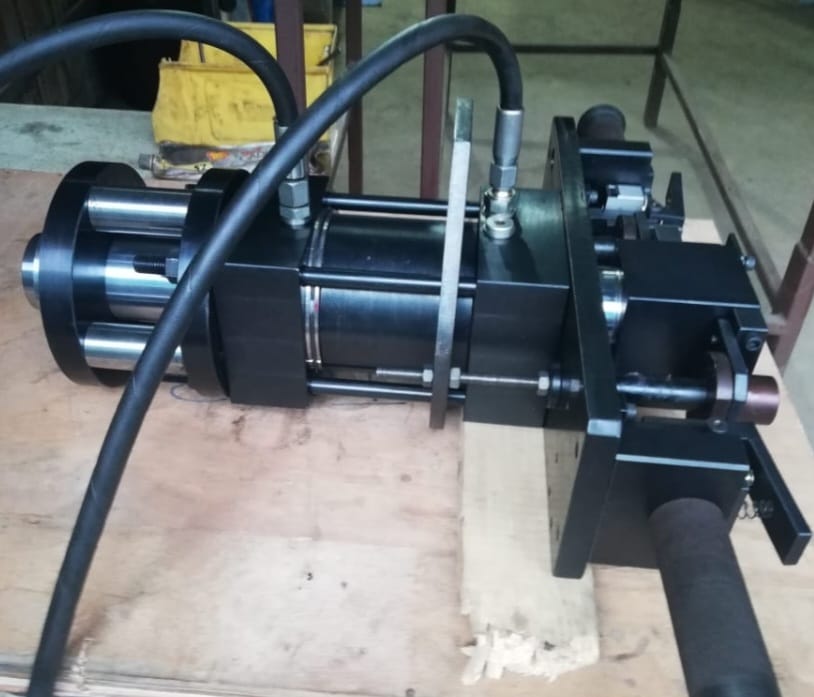

Hydro Pulsation Test Rigs for Engine Crank Case and Liner

> Hydraulic Pressure 0 to 350 bar based on ISO 4548 -5-2013(E) Standard -

Hydro Pulsation Test Rigs for High Oil Pressure Testing

> Hydraulic Pressure 0 to 400 bar based on ISO4548 -5-2013(E) Standard -

Hydro Pulsation Test Rigs with Low Viscous Oil for Cylinder Heads

> Hydraulic Pressure 70 bar based on ISO4548 -5-2013(E) Standard

-

Hydro Pulsation Test Rigs for Engine Rocker Covers using Air

> Air pressure 0 to 7 bar based on ASTM F-37 Standards -

Test Rigs for Engine Lubrication Oil Pump Durability Test

> Flow and Pressure was measured, Relief Valve was tested for opening. ISO4548 -5-2013(E) Standard was referred for designing the SCADA based Test Rig -

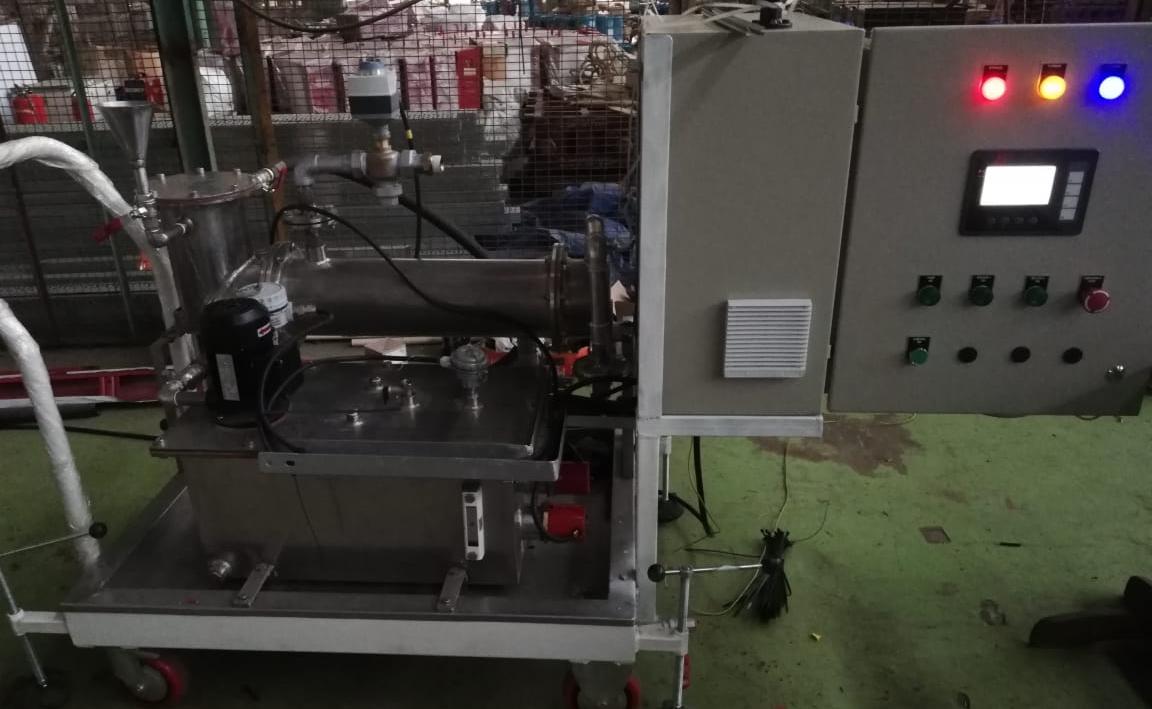

Test Rigs for Engine Coolant Pump Durability Test

> Flow and Pressure was measured, `ISO4548-5-2013(E) Standard was referred for designing the SCADA based Test Rig.’

- Coolant Temperature Conditioning Units for Engine Testing

- Coolant Temperature Thermal Shock Unit for Engine Testing

- High Pressure and Low Pressure Hydraulic Power Packs

- EV Motors Thermal Test and Soaking Chamber

- Oil Seal Pressing Unit for Engine Assembly

- EOT Cranes 3 Motion Control Panels

- PLC HMI VFD Based Control Panels

- Engineering Colleges Laboratory Equipments and Test Units

- Automated Loading System for Furnaces

- FASD Panel for Hammer Press Machines

OUR STRENGTHS AND EXPERTISE

INDUSTRIAL AUTOMATION

• Test Rigs, Equipment and SPM – Design and Development as per requirement.

• Control Panel Building and Retro fitment using PLCs (Programmable Logic Controllers), HMIs (Human Machine Interfaces) and VFDs (Variable Frequency Drives) of various makes like Mitsubishi, Siemens, AB, Delta etc

• Process Automation and Factory Automation, SCADA Based Projects

• IIoT – Industry 4.0 Based Applications

• Material Handling Automation, Automated Conveyors and Loading System.

• CNC Maintenance, Retro-fitment, Reconditioning work and AMCs

• Energy Auditing, Energy Monitoring System and ENCON Activities

OUR PROUD CLIENTS